Construction Materials and Resources Supplier, Tiles & Stone

TILE GALLERY

In 1956, North America was in the midst of the largest building boom the world had yet seen. Post-war prosperity drove home ownership and new housing starts to unprecedented heights. President Eisenhower’s most notable accomplishment, the interstate Highway System, was just beginning to take form, Cities from coast to coast were being expanded and reshaped.

The American landscape was about to change forever.

New technologies were emerging in almost all trades and industries, and construction was no exception. Mass production techniques were applied to homebuilding and thus in Levittown PA, the “Planned Community” was born. Improvements in steel engineering allowed for taller, lighter structures. Commercial and office building construction took off after decades of stagnation.

Despite vast changes in many construction trades, ceramic tile and stone installation practices remained virtually indistinguishable from 100 or 1000 years prior. Four basic ingredients were required: sand, cement, water, and a lot of labor.

A thick bed of heavy mortar was required to place tiles or stones on walls, floors and countertops. Difficulty in aligning with adjacent finishes meant expensive changes to framing and concrete placement details.

The resulting installation was massive and heavy in a time when buildings were designed to be lighter in weight and more flexible.

All of these factors conspired to limit acceptance and use of ceramic tile. It was used primarily on bathroom floors and walls and on ground level lobbies and kitchens. Total consumption of ceramic tile in the United States in 1955 is estimated at less than 100 million square feet ? or only about 0.6 square feet per capita.

The landscape of the ceramic tile industry also was about to change forever.

While working in his family’s floor covering installation business in South Carolina, Henry M. Rothberg realized that there must be a better way to install ceramic tile.

With a background in science and a degree in Chemical Engineering, Dr. Rothberg began development work with Uniroyal Chemical at their Naugatuck, CT research facility where he investigated synthetic latex technologies that had been applied to the concrete industry.

After much effort and time ? LATICRETE 4237 Latex Thin-Set Additive was developed and taken to market. For the first time a strong, weather and shock-resistant “thin-bed” mortar could be mixed on-site using equal parts of sand and cement, gauged to a workable consistency with LATICRETE 4237.

In 1956, not realizing the potential of what would soon prove to be a revolutionary product, Uniroyal sold the LATICRETE brand to Dr. Rothberg, and LATICRETE brand to DR. Rothberg, and LATICRETE International, Inc. was born.

Initial efforts to promote this new method of tile installation in North America met with resistance.

Having a large family to feed, Dr. Rothberg took his samples and product literature and departed for overseas markets where tile and stone were already much more common finishes. Large installations and long-term relationships followed successful presentations in Europe, the Middle East and Asia.

LATICRETE remained primarily export-focused in its early years. Slowly, North American tile installation firm began to realize the labor-savings benefits afforded by this new and innovative installation system.

Learning from his international experience, Dr. Rothberg focused his efforts on the Architectural community, which could appreciate the significant savings in other aspects of building construction ? less steel, less concrete, no depressed slabs ? when thick, heavy mortar beds could be eliminated.

As LATICRETE grew, the thin-bed method took hold as a typical means of installation. Consumption of ceramic tile grew steadily and rapidly in North America and in 2005 exceeded 3.2 billion square feet (over 10 square feet per capita).

LATICRETE became one of the most prominent product lines available as tile distribution developed around the world in the 1960’s and 1970’s.

As distribution increased, so did the availability of LATICRETE. More and more products were added to the LATICRETE product line that allowed installation of ceramic tile in residential and remodel applications as well as in industrial and commercial construction. LATICRETE became a brand preferred by many types of installers, not just large installation firms focusing on large projects.

Demand for LATICCRETE® products is fulfilled through distribution supported by 6 plants in North America, and a network of factories, distributors and partners around the world.

In the 1990’s LATICRETE sharpened its focus on the international market to create and cultivate efficient local production in expanding markets. This successful strategy has resulted in worldwide local availability of LATICRETE installation materials.

LATICRETE focuses on adding value to the markets it serves, and thus those markets grow in value for all participants.

Always driven by the desire to innovate, LATICRETE has pioneered dozens of industry firsts in products and services. By specializing in the development of products designed for the installation of ceramic tile and stone, a singular focus has been achieved that continues to bring forth products that make tile more durable and economical in virtually all types of applications and climates around the world.

Our commitment to innovation continues today and will continue into the future as we pursue the vision of our founder, Dr. Henry M. Rothberg.

- INTERNATIONAL

- DOMESTIC

INTERNATIONAL

-

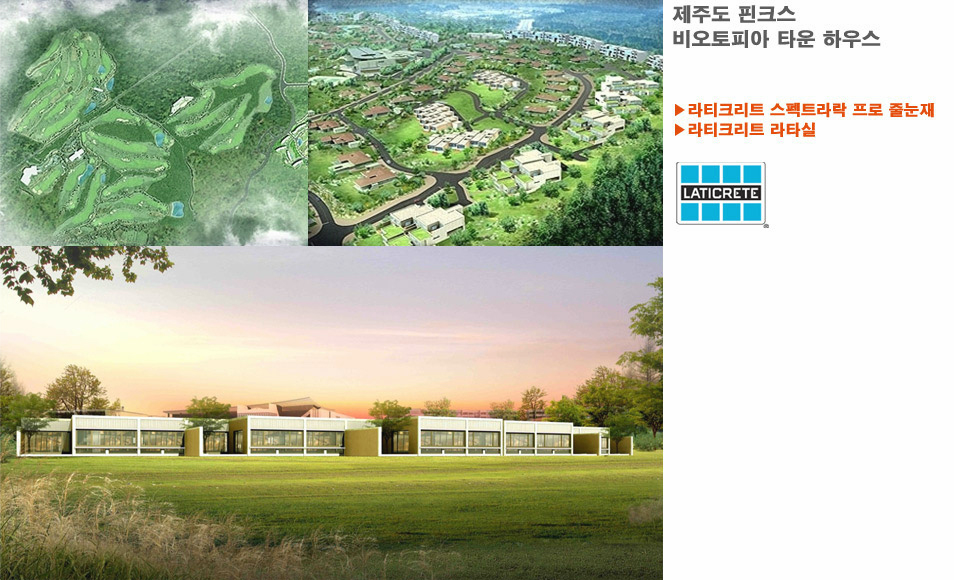

projectno.15

projectno.15

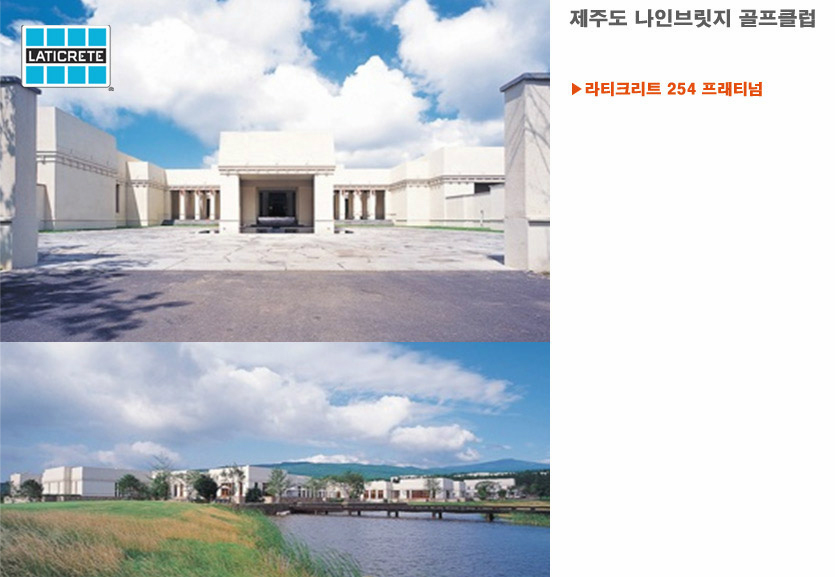

-

projectno.14

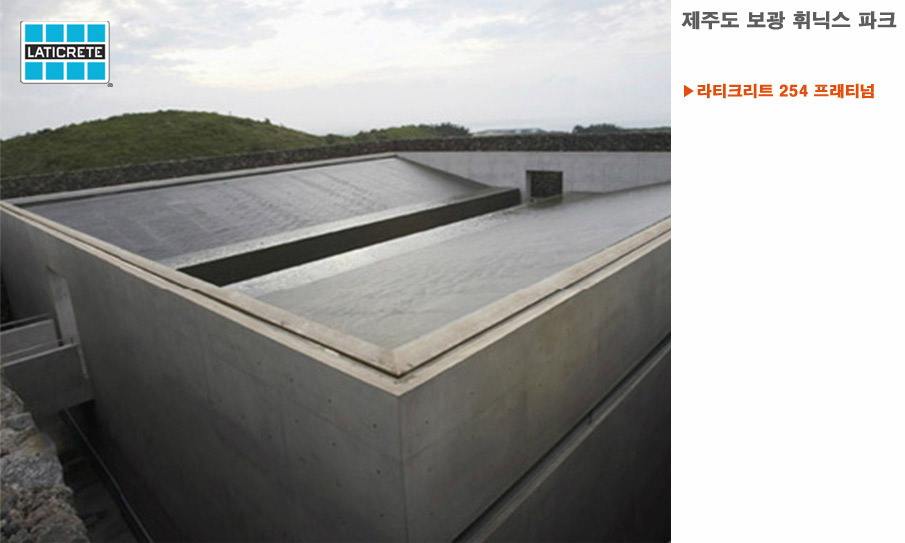

projectno.14

-

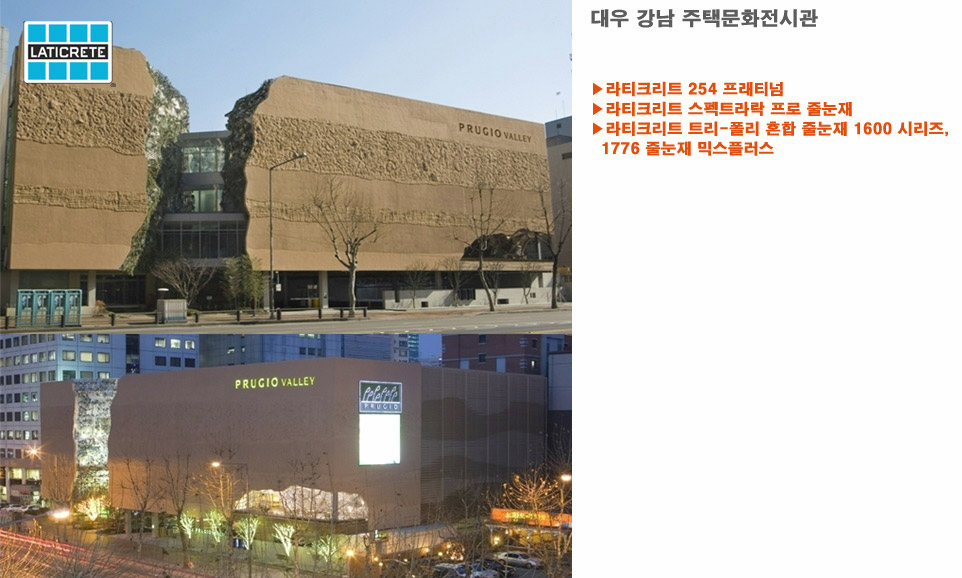

projectno.13

projectno.13

-

projectno.12

projectno.12

-

projectno.11

projectno.11

-

projectno.10

projectno.10

-

projectno.9

projectno.9

-

projectno.8

projectno.8

-

projectno.7

projectno.7

-

projectno.6

projectno.6

-

projectno.5

projectno.5

-

projectno.4

projectno.4

-

projectno.3

projectno.3

-

projectno.2

projectno.2

-

projectno.1

projectno.1

DOMESTIC

-

projectno.10

projectno.10

-

projectno.9

projectno.9

-

projectno.8

projectno.8

-

projectno.7

projectno.7

-

projectno.6

projectno.6

-

projectno.5

projectno.5

-

projectno.4

projectno.4

-

projectno.3

projectno.3

-

projectno.2

projectno.2

-

projectno.1

projectno.1

laticrete.co.kr

laticrete.co.kr